• Robotic process automation (RPA) effectively automates repetitive processes while reducing human error.

• Industry 4.0 solutions are revolutionizing manufacturing operations by combining physical equipment with digital technology such as AI and IoT.

• Augmented reality (AR) enables manufacturers to create engaging customer experiences while collecting valuable product feedback.

• Photoelectric sensors can automate assembly line operations, detect product defects, and measure objects.

• Data analytics provides businesses with insights into customer behavior and product performance.

In the 21st century, technology has revolutionized almost every aspect of life. As a business owner, it’s essential to stay up-to-date with the latest technological advances that can give your business an edge over competitors. This is especially true for manufacturing businesses, where technology can make processes more efficient and cost-effective. Here are some of the technologies that you should consider investing in to give your manufacturing business a boost this 2023:

Robotic Process Automation (RPA)

Robotic process automation (RPA) is rapidly becoming popular for businesses looking to reduce costs and increase efficiency. RPA automates repetitive tasks and processes, freeing employees’ time and energy for more creative and innovative tasks. With RPA, your company can improve accuracy and speed while reducing human error, ultimately improving customer satisfaction and increasing profits. Additionally, RPA can help you stay compliant with industry regulations by providing an audit trail of all activity.

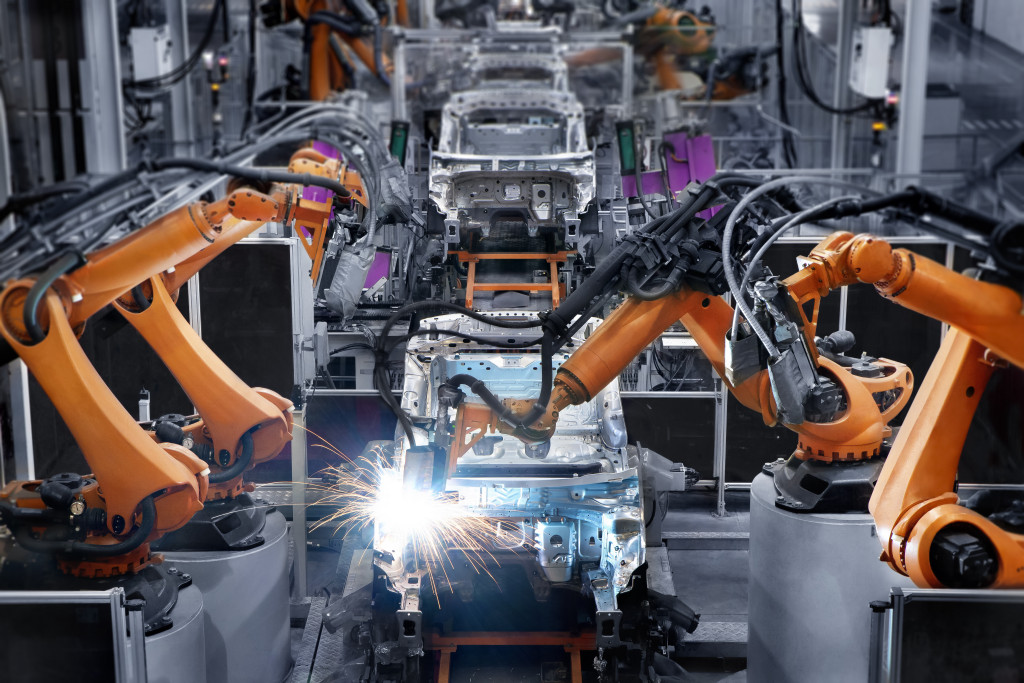

Industry 4.0 Solutions

Industry 4.0 solutions offer manufacturers a way of monitoring their operations more closely than ever by combining physical equipment with digital technology such as artificial intelligence (AI) and the Internet of Things (IoT). These solutions enable companies to collect real-time data on their equipment performance which allows them to optimize production processes and reduce operational costs significantly – resulting in higher profits over time. Industry 4.0 solutions also allow companies to quickly identify any problems within their operations, which helps them address issues quickly before they become major problems that could lead to lost revenue or downtime due to repairs being made late or incorrectly.

Augmented Reality (AR)

Augmented reality (AR) is becoming increasingly popular among manufacturers who want an immersive experience for their customers or employees when using products or services provided by the company – enabling them to get a “realistic” view of what it would be like using the product without actually having physically interact with it beforehand.

AR provides users with interactive visuals that overlay onto real-world objects through devices such as smartphones or tablets – allowing manufacturers to create engaging experiences for their customers while also gaining valuable feedback from users on how well-designed their products are. AR technology has been used successfully by many manufacturing companies already, so there is no doubt it will continue its rise this 2023.

Photoelectric Sensors

Photoelectric sensors use light to detect and measure objects. The technology is used in a variety of industries, from automotive production to food manufacturing. By leveraging photoelectric sensors, companies can greatly improve their processes – from automating assembly line operations to detecting product defects before they reach the customer. Photoelectric sensors are incredibly accurate and reliable, making them an ideal solution for modern manufacturing businesses looking to stay ahead of the competition.

Data Analytics

By leveraging data analytics tools, companies are able to gain valuable insights into their customers’ needs and preferences. This will allow you to:

Identify market trends

By using data analytics to identify trends in customer behavior, companies can develop new products and services that are more likely to be successful.

Optimize production processes

Data analytics can be used to analyze the efficiency of a manufacturing process and identify areas where improvements can be made – leading to increased profits over time.

Improve customer satisfaction

Data analytics can help provide a better overall customer experience by giving you an in-depth understanding of your customer’s needs and preferences.

Track the product performance

Data analytics can provide manufacturers with detailed insight into how their products are being used, allowing them to identify any issues that may arise and address them quickly.

By utilizing data analytics, you can gain a comprehensive view of your manufacturing operations and use the data to make more informed decisions that will ultimately result in improved profits and customer satisfaction.

To stay competitive in the manufacturing industry, businesses must invest in cutting-edge technology. From robotic process automation (RPA) and cloud computing services to augmented reality (AR), photoelectric sensors, and data analytics – there are a variety of technologies that can help your business improve efficiency and reduce costs while gaining valuable insight into customer behavior. By leveraging these technologies this 2023, you will be able to give your manufacturing business an edge over competitors and achieve greater success than ever before.